Asset-heavy enterprises can no longer operate with blind infrastructure. The old model of scheduled maintenance and centralized analytics is breaking under regulatory pressure and reliability risk. Leaders who fail to embed intelligence at the edge will lose uptime, margins, and service relevance. This report explains what changes now and what’s essential for real-time decision-making, operational resilience, and newer business models.

With physical AI or edge AI, manufacturing leaders and operations heads can turn brownfield environments into intelligent systems that predict failures, optimize energy use, enable remote operations, and even monetize reliability as a service. In industries where margins are thin and downtime is costly, embedding intelligence into physical assets is no longer optional; it’s the next competitive frontier.

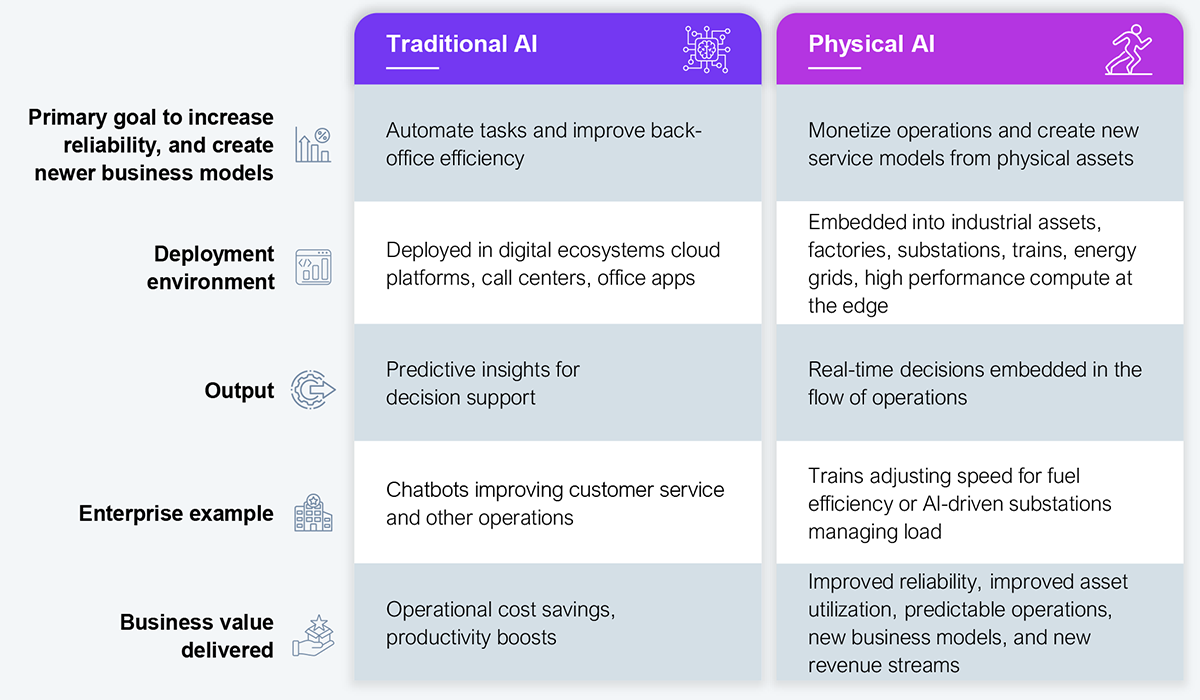

By embedding edge AI into rail systems, energy grids, and smart factories, Hitachi is not just automating processes. It’s creating new revenue models, shortening grid connection timelines, and redefining service delivery. This isn’t just about IT efficiency; it’s a reinvention of the entire business model (see Exhibit 1).

Source: HFS Research, 2025

HMAX is Hitachi’s physical AI-driven portfolio of solutions built with NVIDIA. It places AI directly onto operational assets, from 300km/h trains to legacy substations. Many solutions run on NVIDIA IGX cards, enabling high-performance compute at the edge. HMAX delivers real-time insights and autonomous control for both new equipment and in brownfield environments where most enterprises already operate.

Key breakthroughs include:

Edge AI is no longer about pilots but about driving improved operations. If your operational assets aren’t making real-time decisions, they’re deadweight. Treat them like products, not pipes. Audit every legacy system for AI application potential before your competitor does.

Most providers stop at performance improvement, but Hitachi goes a step further by using its edge AI infrastructure to unlock entirely new revenue streams. In UK rail, onboard sensors deliver real-time operational insights, allowing Hitachi to monetize reliability as a service and offer uptime-as-a-service or predictive maintenance subscriptions to infrastructure managers. The result: data is turned into recurring revenue. If you’re not productizing performance, someone else will. Enterprises must identify which parts of their infrastructure, such as reliability-as-a-service, predictive maintenance, or real-time performance data, can be productized.

In the energy sector, AI-enabled substations not only optimize load balancing but also enable Hitachi to license its AI grid optimization tools or offer grid connection acceleration as a premium service, addressing utilities’ urgent need to integrate renewables faster. In manufacturing, AI-guided inspection and digital twins reduce downtime and enable outcome-based contracts such as pay-per-hour uptime models or efficiency-as-a-service offerings, while also opening the door to subscription-based digital twin services through Hitachi HMAX. In all three industries, Hitachi is transforming traditional one-off infrastructure sales into scalable, service-based revenue models.

Here’s the differentiator: Hitachi uses its own factories, trains, and grids as live testbeds. This “customer zero” model means every deployment has already been run at an industrial scale before it’s offered to clients. Few IT services firms have that level of ownership or operational context.

Hitachi also builds domain-specific AI models rooted in actual operational behavior—not generic LLMs. With NVIDIA’s full software stack and domain talent in the mix, the collaboration brings precision AI to asset-intensive industries that have long struggled with digital ROI. Enterprises should ask their vendors: “Where have you deployed this at scale in your own operations?” If the answer is “nowhere,” you’re their guinea pig and not their client.

Manufacturing leaders and operations heads can’t afford to treat physical infrastructure as dumb pipes or passive assets. Hitachi’s collaboration with NVIDIA shows what happens when you embed intelligence at the edge, integrate it with real operational data, and monetize the outcome.

Forget AI pilots and chatbot demos. Start with assets that move your business. Hitachi’s physical AI models offer a repeatable playbook: a high-stakes testbed, domain-specific expertise, and global scaling through a portfolio of offerings such as HMAX and Lumada.

If your trains, turbines, and grids aren’t making AI-driven decisions today, you’re already behind. Turn your infrastructure into a profit center or risk becoming your competitor’s use case.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started