Lubricants and petrochemical enterprises face unprecedented pressure as the energy transition, regulatory upheaval, and shifting demand converge at speed. Product lifecycle management (PLM), long relegated to back-office file storage, now has a more urgent role. It must become the digital infrastructure that aligns R&D creativity with operational discipline and ensures the entire value chain moves precisely. Traditional PLM systems are built for control, not agility, and can’t support the urgent need to innovate cleaner, comply smarter, and adapt faster. To thrive, these firms must rethink PLM as a strategic command center that connects R&D, compliance, and sustainability across the product lifecycle.

Today’s PLM solutions are no longer just digital filing systems—they now integrate advanced capabilities such as AI-powered formulation prediction, real-time regulatory tracking, and automated sustainability assessments. Leading petrochemical companies are already reaping the benefits of this transformation. BASF, for instance, has leveraged digital PLM to reduce new formulation development time by 25%, enabling faster response to evolving customer demands and compliance requirements. Shell Chemicals utilizes PLM to facilitate real-time data access across its global teams, resulting in 20% faster innovation cycles for sustainable lubricant formulations. Meanwhile, Dow Chemical has implemented an integrated PLM-regulatory framework that has reduced compliance-related delays during product launches by 40%. These examples illustrate how modern PLM is becoming essential for accelerating innovation and ensuring regulatory readiness in a rapidly evolving industry.

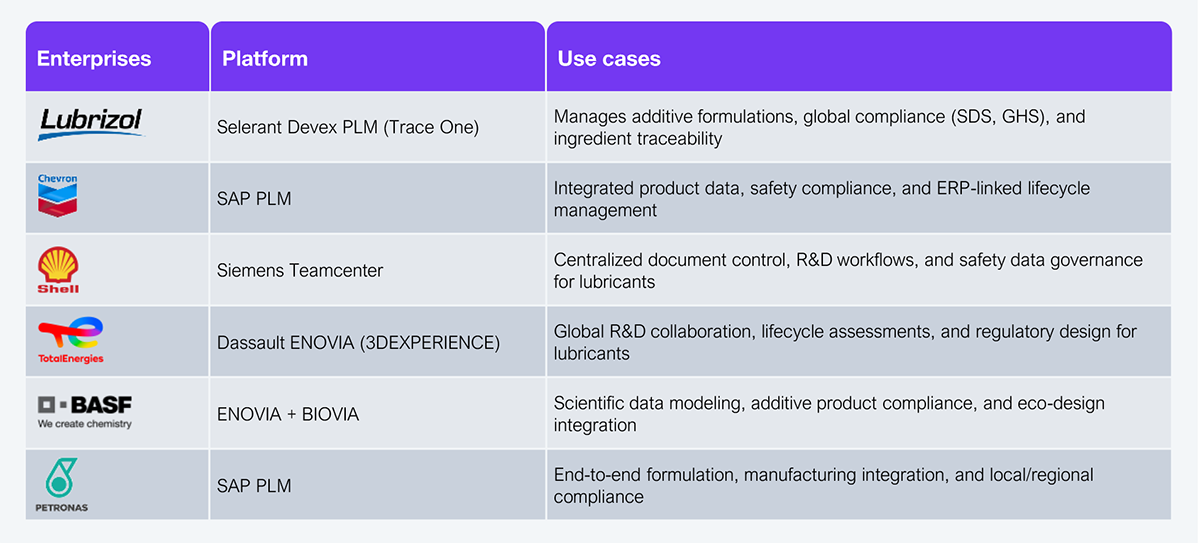

Enterprise leaders aren’t buying PLM for feature parity—they’re making hard choices about how to scale regulatory agility, R&D productivity, and ESG accountability (see Exhibit 1).

Source: HFS Research, 2025

Here’s how leading firms are navigating these decisions:

Shell Chemicals: Standardizing compliance with Siemens Teamcenter

Shell needed to harmonize safety and documentation workflows across global R&D sites. Siemens Teamcenter offered centralized data governance, enabling Shell to align product documentation, regulatory traceability, and innovation timelines.

Enterprise trade-off: Shell had to restructure internal processes and normalize legacy data to make the system effective. The result was faster compliance turnarounds and reduced audit risks.

TotalEnergies: Embedding sustainability in R&D with Dassault ENOVIA

To comply with the growing ESG mandates, TotalEnergies leveraged ENOVIA’s simulation and lifecycle tools to assess environmental impact during early formulation.

Enterprise insight: ENOVIA enabled sustainability-driven design choices but demanded new cross-functional workflows and cultural change in R&D. It was less about tools and more about behavior.

Chevron and Petronas: Operationalizing safety with SAP PLM

With PLM embedded in SAP ERP, these firms gained tighter alignment between lab formulation, plant manufacturing, and safety compliance.

Enterprise trade-off: While integration was strong, flexibility was limited. Custom extensions were needed to accommodate niche petrochemical processes.

Lubrizol: Managing regulatory volatility with Trace One Devex PLM

Operating across diverse regulatory environments, Lubrizol used Trace One Devex PLM to automate GHS labeling and trace additives and adapt quickly to market-specific requirements.

Enterprise benefit: Granular traceability enabled Lubrizol’s agility in compliance, but it depended on constantly tuning regulatory rules and tight feedback loops with regional teams.

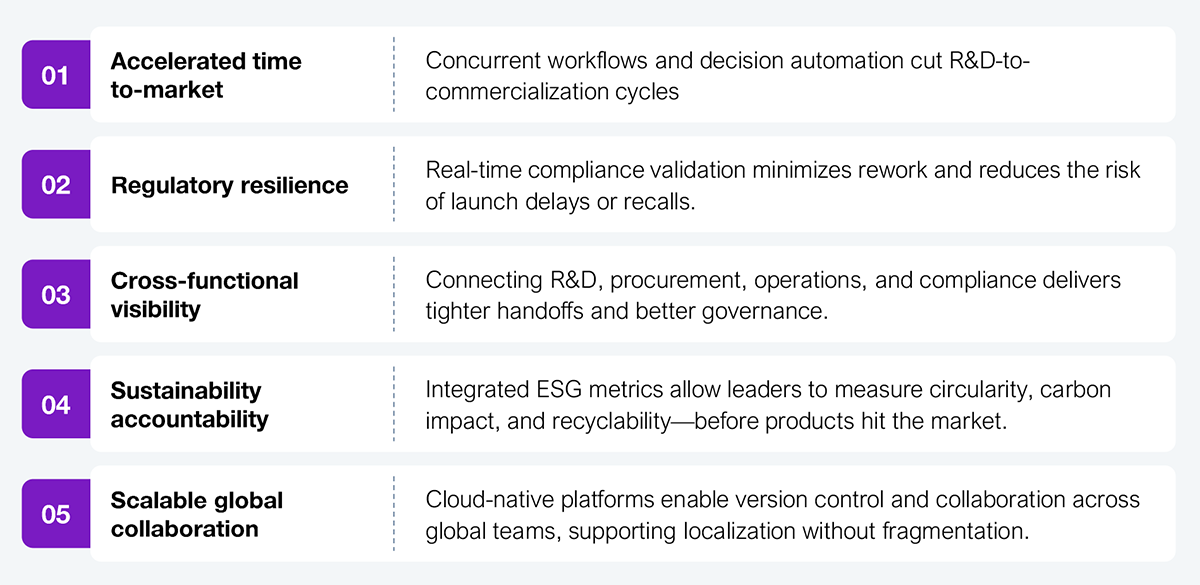

Modern PLM investment is not about upgrading IT. It’s a business-critical decision to de-risk operations, accelerate growth, and enable transparency across product lifecycles (see Exhibit 2).

Source: HFS Research, 2025

Modern PLM systems are evolving from static data repositories into dynamic, strategic platforms that address the growing complexity of product development and global operations. They accelerate time-to-market by supporting concurrent workflows and automating decision-making, helping organizations reduce delays between R&D and commercialization. However, without real-time visibility and cross-functional collaboration, these gains are often undermined by inefficiencies and rework. Additionally, PLM’s role in regulatory resilience is becoming critical as companies face increasingly complex compliance demands across regions. While real-time validation tools help, many organizations still operate reactively, risking non-compliance due to the constant evolution of regulatory requirements.

Beyond operational improvements, next-gen PLM systems support strategic priorities such as sustainability and global collaboration. By embedding ESG metrics directly into product development, leaders can make sustainability-first decisions around recyclability, carbon impact, and end-of-life considerations, long before launch. Furthermore, cloud-native PLM enables seamless collaboration across global teams, with real-time version control and localization capabilities that preserve core data integrity. This fosters a unified product strategy while empowering local teams to innovate at speed, eliminating the fragmentation and delays that often come with regional misalignment. Together, these capabilities redefine PLM as a central enabler of growth, compliance, and responsible innovation.

Forward-looking enterprises are no longer asking if they should modernize PLM—they’re asking how far it can take them.

Expect these shifts:

But these gains aren’t plug-and-play. They require investments in master data, process alignment, and cultural change.

Petrochemical enterprises can’t afford to treat PLM like a glorified file cabinet. It must become the digital command center that connects innovation with compliance and agility with accountability.

Enterprise leaders must act now, not because the tools are ready but because the market is not waiting. Build data foundations, cross-functional workflows, and governance models that turn PLM from passive to predictive. In a sector where the pace of change is relentless, the future belongs to those who industrialize innovation.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started