Factory managers today are under pressure to program and integrate robots and devices such as humanoids, drones, and autonomous vehicles. Tesla’s Model 3, for instance, saw delays in scaling up manufacturing in 2018 due to what Elon Musk called “excessive automation” and too many robots. To avoid such pitfalls, physical AI is an effective approach for efficient, cost-effective planning, simulation, programming, and ongoing operation of automation equipment.

NVIDIA CEO Jensen Huang recently spoke about physical AI as the “ChatGPT” moment around the corner for robotics. Beyond factories, Boston Dynamics uses large behavior models (LBMs) to train its humanoid robots. LBMs extend large language models (LLMs) beyond text to multiple sensor inputs, actions, and behavior.

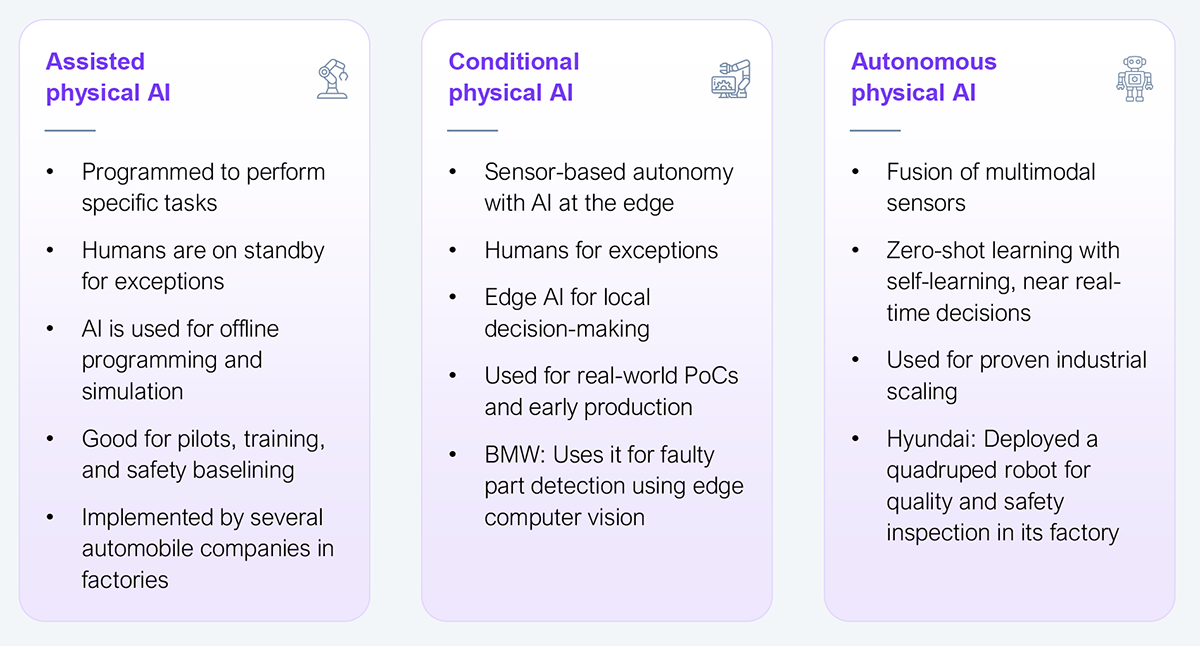

We define physical AI as software-led services embodied in physical systems (robots, humanoids, vehicles, industrial equipment) that perceive, decide, and act with interoperability in the real world, operating autonomously, and delivered and monetized as productized services. With the aging demographics, geopolitical issues, and strained human talent mobility across countries, physical AI emerges as a timely and strategic solution. Manufacturers must choose the appropriate level of physical AI—assisted, conditional, or fully autonomous systems—based on their maturity in AI adoption, business needs, and appetite for investment (see Exhibit 1).

Source: HFS Research, 2025

Physical AI offers zero-shot training, where robots can categorize and recognize unfamiliar objects using computer vision, perform new tasks, and handle unforeseen scenarios using pre-trained models. The World Economic Forum considers physical AI as the technology that enables next-generation industrial operations. The International Federation of Robotics identified the usage of AI as the top trend for robots in 2024.

NVIDIA’s Omniverse™ is one such physical AI platform that develops applications in 3D environments. Siemens, in partnership with NVIDIA and AWS, accelerated the planning of FREYR’s battery cell gigafactory setup by creating a digital twin of the operations to simulate and make rational engineering decisions.

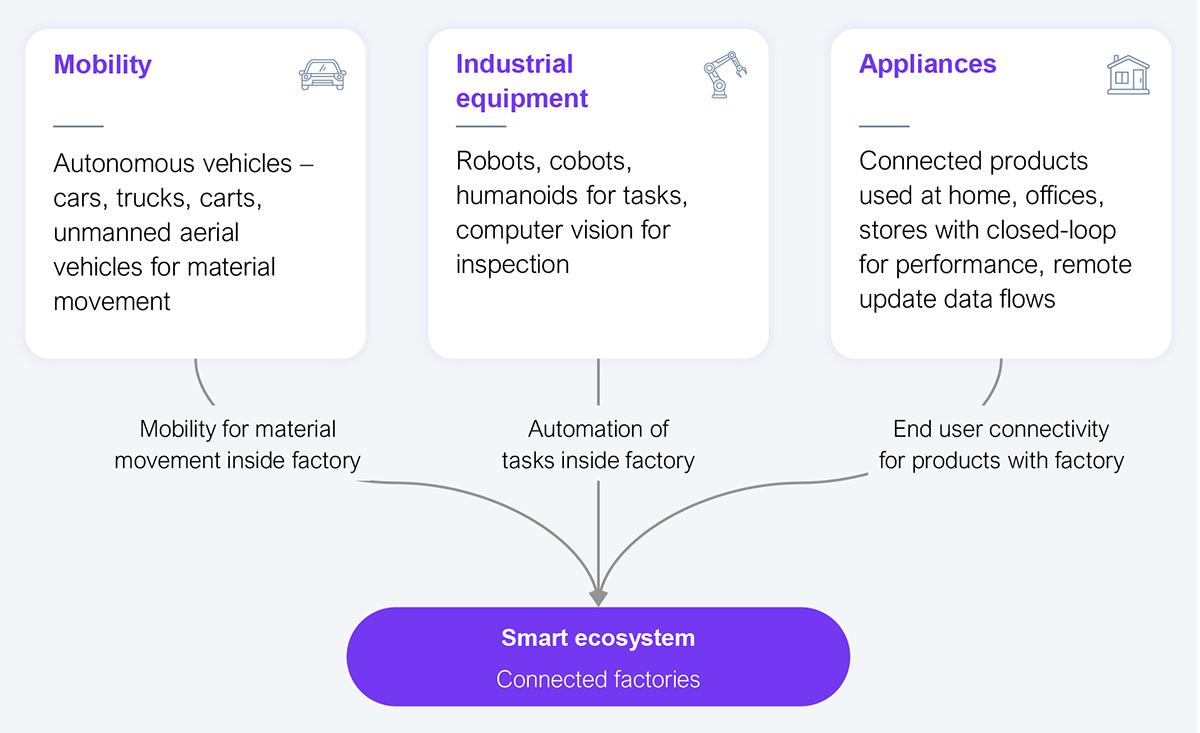

Physical AI applications broadly fall under four categories: (1) smart ecosystems, like an office or factory, (2) mobility devices such as driverless cars, trucks, and drones, (3) industrial equipment such as robots and cobots, and (4) home appliances (see Exhibit 2). A car is an example of a product moving from a factory to the garage and beyond, illustrating how these categories are interconnected across the life cycle.

Source: HFS Research, 2025

Despite the promises of physical AI, the major barrier to adoption is the lack of data for training, including 3D spatial intelligence. Training physical AI requires data from real-life environments such as sensor, actuator, and manipulator data, much like text data for training LLMs. Unlike text, which is discrete and non‑physical, real-world data is continuous, far more complex, and as valuable as currency—to be monetized.

Physical AI couples perception with logical reasoning and control, with real‑time feedback loops and safety envelopes. It needs simulated and real data from trajectories and force/tactile data, progressing to cross‑robot datasets for interoperability from diverse classes of industrial assets. LLMs use prompt engineering, while physical AI maps pixels and actions.

The robotics foundation models that Toyota promotes collect robot movement data from diverse environments to learn and adapt to various tasks. Robot manufacturers are developing generative AI-driven user interfaces to use natural language processing to program robots. Factory managers should leverage such initiatives, along with their own historical records and technology partners, to curate pre-training data for physical AI.

Physical AI faces other operational challenges around human safety and cybersecurity. The US Occupational Safety and Health Administration (OSHA) recorded 77 robot-related accidents between 2015 and 2022, highlighting the real-world risks posed by automated systems operating alongside humans.

Smart home appliances, such as voice-enabled air fryers, were found to compromise user privacy by recording voices unrelated to their functions and transmitting that data to the manufacturer. On a larger scale, the Cybersecurity and Infrastructure Security Agency recently issued a security alert about the vulnerabilities in railway brake control systems, potentially allowing hackers to command train operations and cause a catastrophe.

To mitigate such risks, factory managers must take the lead in ensuring the physical and cyber safety of AI-powered systems. This requires planning, designing, and implementing guardrails during the initial stages of the product lifecycle, not as an afterthought after they are designed or manufactured.

Manufacturing equipment must simulate, sense, think, act, and learn to avoid automation glitches. You are not automating just machines, but an adaptive workforce to work in collaboration with humans, other equipment, and enterprise-level systems. Physical AI is the only scalable path that gives traditional automation the sentience, cognition, and autonomy to ensure that automation objectives are met.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started