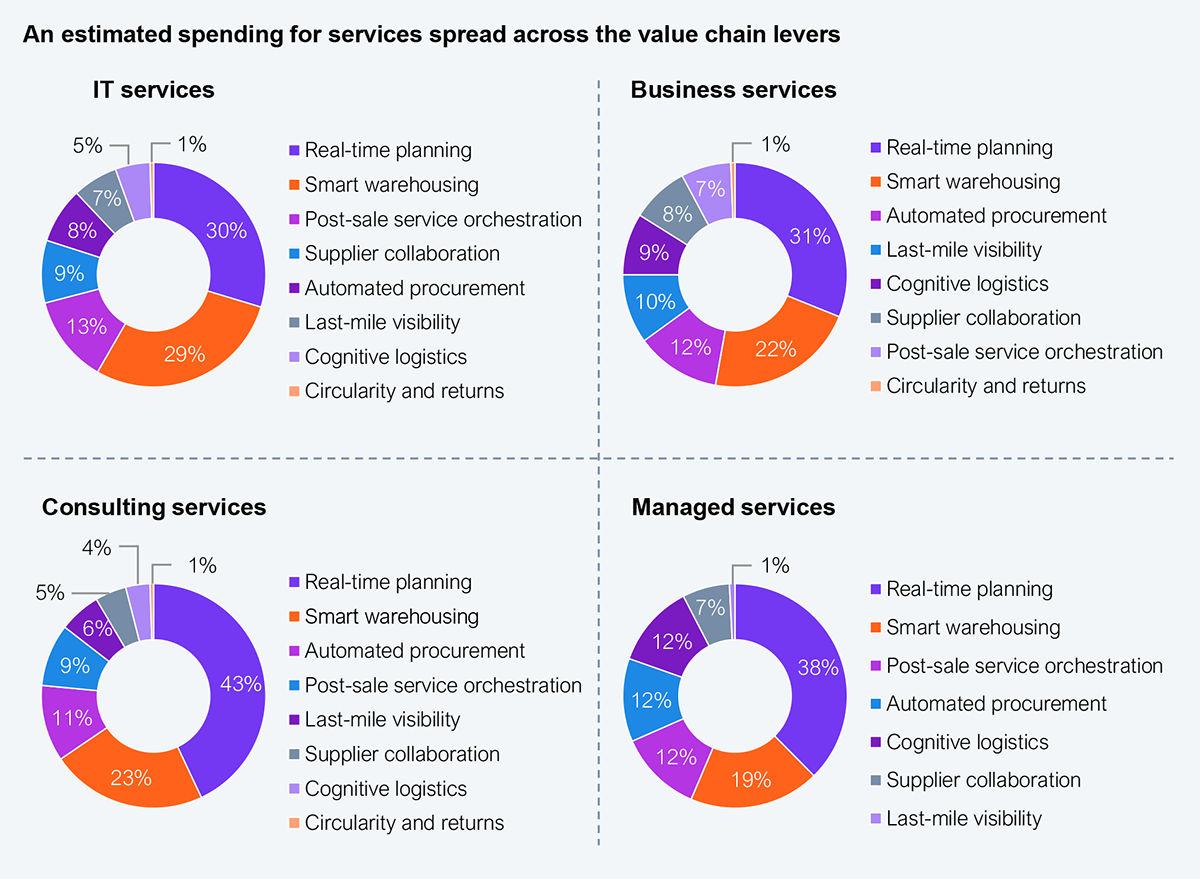

Supply chain leaders don’t necessarily need an entirely new strategy; rather, they benefit more from sharpening their focus on what truly drives value. Data from our upcoming Horizons report on intelligent supply chain shows that four primary capability areas—real-time planning, smart warehousing, post-sale orchestration, and automated procurement—consistently account for more than 70% of total spending across consulting, business processes, managed services, and IT implementations (Exhibit 1), reflecting where enterprises are seeing the fastest and most measurable returns.

These four capabilities address long-standing supply chain inefficiencies that are magnified during disruptions. From mitigating inventory risk to accelerating order cycles, they have a direct impact on financial performance and customer satisfaction. Leaders are under pressure to show outcomes fast, and these areas provide the most straightforward path to delivering results at scale without overhauling the entire operating model.

Sample size: 10 customer references

Source: HFS Research, 2025

Real-time planning, smart warehousing, post-sale orchestration, and automated procurement form the digital backbone of a modern, customer-focused supply chain.

These capabilities are the operational levers that release working capital, reduce cycle times, improve safety, and enable a seamless customer experience. When enterprise leaders focus on real-time planning, smart warehousing, post-sale orchestration, and automated procurement, they are employing strategies that can significantly impact business results.

Many are already experiencing the benefits of strategic planning. Cognizant partnered with a prominent US-based automotive manufacturer to implement integrated planning and real-time tracking, driving +10% profitability and +50% site-level operational efficiency. Likewise, Infosys partnered with an American cosmetics company to consolidate planning via an offshore model, reducing cycle times by 40% and costs by 30%.

While concentrating investment within the core areas generates significant value, there’s the risk of neglecting adjacent capabilities. Underfunding areas at the periphery, such as circularity, cognitive logistics, post-sale orchestration, and last-mile visibility, can lead to brittleness in the supply chain, potentially limiting an organization’s agility and resilience in the long run. The risk isn’t immediate failure; it’s the slow build-up of organizational debt.

Moreover, regulatory pressures surrounding sustainability and circularity are intensifying and becoming more stringent, while customer expectations on transparency and service precision, especially in last-mile fulfillment, are rising rapidly. Being prepared for disruptions is now a baseline condition, not an exception. Enterprises that can’t dynamically reroute around bottlenecks or anticipate service failures through AI are already at a disadvantage. Investing in cognitive logistics, traceability, and closed-loop returns is no longer experimental but a necessity.

Supply chain leaders must ensure that every investment in the core lays the groundwork for what follows. This means choosing platforms and partners that not only solve today’s challenges but are modular and future-ready. Integration flexibility, data interoperability, and AI extensibility must be non-negotiable. Providers should deliver more than mere implementation; they must bring strategic foresight, domain-specific accelerators, and embedded intelligence. Those that only optimize the core without building the connective tissue to edge capabilities risk boxing clients into brittle architectures. The key is to hold them accountable for co-creating roadmaps that strike a balance between short-term impact and long-term adaptability.

Supply chain leaders must strike a balance between targeted investment in core capabilities and a readiness to evolve at the edges. Modern supply chains are not linear; they’re dynamic, adaptive ecosystems. If your partners can’t deliver flexibility at scale, it’s time to challenge them or replace them.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started