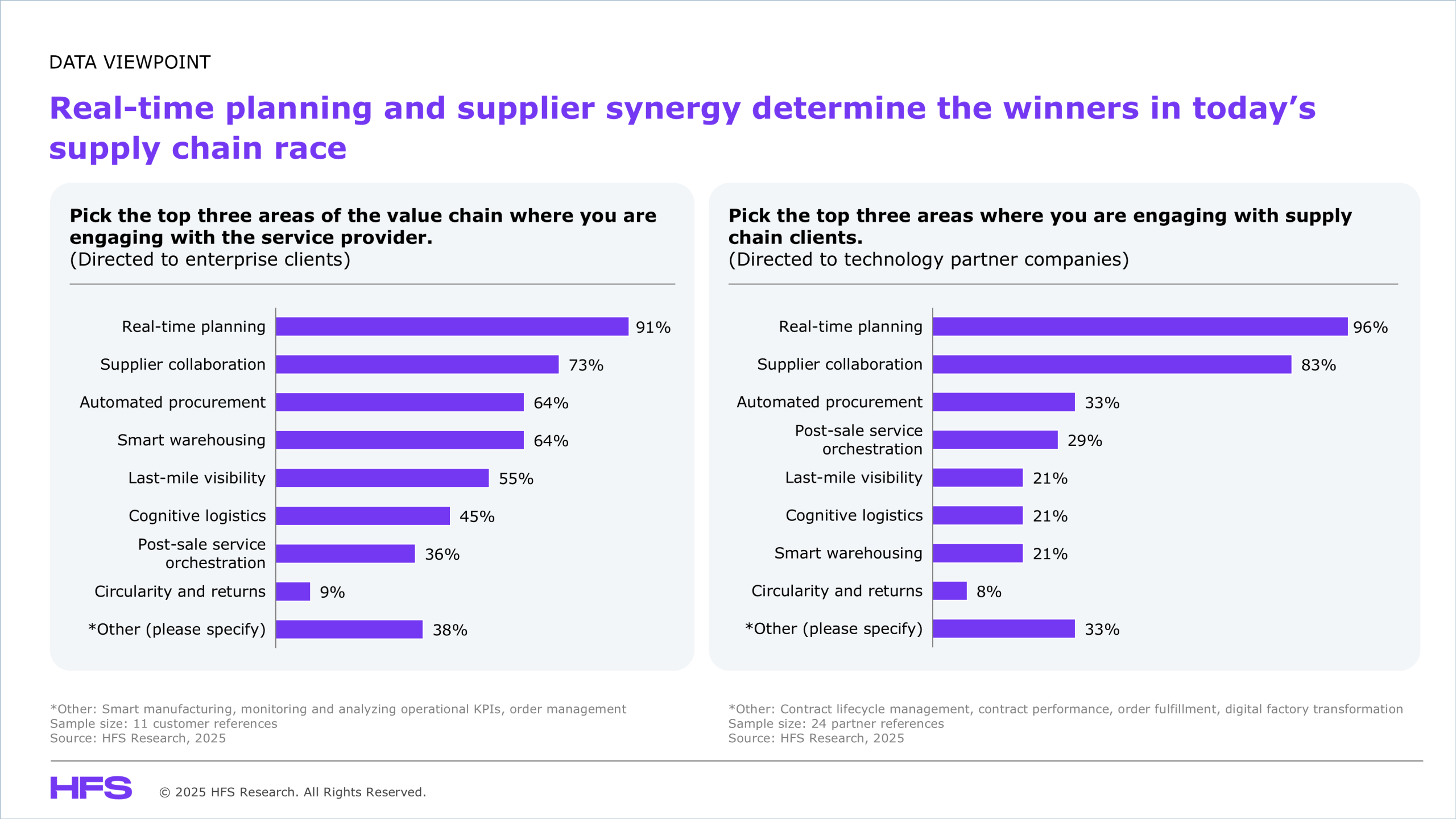

Real-time planning has become the backbone of modern supply chains, and enterprise clients are prioritizing it to gain agility in a volatile environment: With 91% of them engaging with vendors for real-time planning, it’s clear this capability is no longer optional. Market conditions, customer preferences, and supply disruptions can change rapidly, and outdated planning systems often struggle to adapt quickly enough. Real-time planning enables organizations to transition from static, periodic planning to dynamic, scenario-based decision-making, utilizing live data across the entire supply chain.

For example, TCS developed an AI-powered planning solution for a German multinational pharmaceutical and biotechnology company, combining predictive and generative AI to drive real-time SKU-level decisions. EY used the Aera platform to automate the top 100 supply chain decisions for a client, enabling ~70% autonomous decisions, an 8–10% increase in forecast accuracy, and a 1–2% service improvement.

Supplier collaboration is emerging as a top priority because enterprises recognize that resilience isn’t built in isolation: With 73% of clients focused on enhancing collaboration across supplier networks, businesses are investing in platforms that enable shared visibility across platforms, integrated planning tools, and digital collaboration hubs to ensure supply continuity, transparency, and faster response times. Today’s supply chains are interdependent, and disruptions in tier-2 or tier-3 suppliers can cripple operations. Traditional supplier management is reactive and transactional. Businesses can shift to proactive planning only by fostering collaboration, achieving better quality, improved compliance, and faster innovation. This also helps build trust, which is essential when demand is uncertain and materials are scarce.

Genpact helped a global retail major redesign its General Financial Rules (GFR)-buying organization by implementing system-enabled supplier negotiations, which improved sourcing speed by 20% and integrated over 30 category groups into a unified platform. For a global technology company focused on power grid technologies, Infosys harmonized S2P on SAP S/4HANA and Ariba and automated processes via Ariba Supply Chain Collaboration, achieving 90% of indirect PO lines from AGB and an 80% faster requisition-to-order cycle time.

Automated procurement is gaining traction as enterprises seek to eliminate manual bottlenecks and improve compliance at scale: Automated procurement is a strategic focus for 64% of enterprise clients looking to eliminate manual processes, reduce costs, and enhance decision-making speed. Traditional procurement is slow, error-prone, and heavily reliant on human intervention for routine tasks such as RFQs, vendor comparisons, and contract approvals. Automation transforms procurement by leveraging AI, machine learning, and robotic process automation (RPA) to automate repetitive tasks, identify risks, and ensure compliance. It enables procurement teams to focus on value-adding activities such as supplier development, sustainability, and innovation sourcing. It also helps organizations enforce policy adherence, manage maverick spending, and streamline global procurement operations across multiple geographies.

AI, machine learning, and RPA are automating the procurement lifecycle, accelerating decision-making, enhancing compliance, and reallocating human talent to strategic tasks. EY and Pactum AI implemented automated negotiations for a German luxury outerwear and clothing company, generating outcome-based savings and establishing a scalable tail-spend management program in three years. Mindsprint used Proverse tools (ProBot, ProReporter, ProVal, Spend Classifier) to implement AI-driven e-sourcing and e-bidding for Olam Agri, delivering a 60–80% reduction in sourcing time, 4–6× faster AI-reviewed RFPs, 99% automated compliance checks, and over $100 million in spend managed via ProcureSPRINT.

Enterprises that treat supply chain planning, procurement, and supplier collaboration as periodic, siloed functions are exposing themselves to failure. Real-time planning, AI-driven automation, and collaborative supplier ecosystems are no longer nice-to-haves; they are essential tools for business survival. Leaders must act now to integrate real-time intelligence across the supply chain. Waiting means falling behind while competitors optimize, automate, and innovate at every corner of the value chain.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started