Manufacturers don’t need more automation; they need automation that ‘thinks.’ While leaders are wrestling with labor gaps, cost pressure, and market volatility, agentic AI is already rewriting the rules. This autonomous system makes decisions, fixes disruptions, and reroutes production without waiting for human command. If your strategy is still focused on traditional automation, you’re not leading—you’re lagging.

Agentic AI operates independently, identifying and acting on goals in real time without waiting for commands. These systems are already in live environments, enhancing speed, accuracy, and reliability. If you’re still developing your automation strategy, you’re falling behind.

According to the HFS Research pulse survey of Global 2000 manufacturing companies in 2025, more than 44% plan to replace human-led services or business processes with AI-led solutions in the next two years. Leaders who were part of the survey identified AI-automatic and agentic systems, RPA and workflow orchestration, and predictive and prescriptive analytics as their top three technology investments (see Exhibit 1).

Sample: 16 Forbes Global 2000 manufacturers

Source: HFS Research Pulse, 2025

Agentic AI is already transforming operations across industries by moving routine decisions from humans to autonomous digital agents. What began as predictive insights is gradually evolving into decision-making autonomy, enabling systems to anticipate problems, schedule work, coordinate production, and optimize logistics, often with minimal or no human intervention. The systems can interact laterally, communicating with other factories and working alongside humans to augment, not replace, industrial talent.

Leading manufacturers are already seeing real-world impacts. BMW’s agentic maintenance agents cut unplanned downtime by 18%. Samsung’s AI-led procurement system helped alternative suppliers reduce material costs by 7% during a regional disruption. Bosch implemented adaptive quality control that adjusts in real time to changes in material quality, reducing cycle times by 25% without increasing headcount.

Likewise, GE Aerospace’s digital twin-driven maintenance agents reduced unscheduled engine removals by a third. Tesla’s Gigafactories dynamically redistribute production across plants without centralized control, cutting delivery times by 20%. ABB used agents to improve robotic task sequencing and alignment accuracy, eliminating human bottlenecks in high-precision assembly.

These aren’t edge-case wins; they’re early indicators of where industrial performance is headed. To keep up, act now—start small but think big. Identify one high-impact area (such as maintenance or quality control) where agentic AI can deliver quick wins and scale from there. Invest early in building data foundations, interoperable systems, and workforce readiness so that AI agents can operate seamlessly and safely. More importantly, adopt a mindset shift: move beyond traditional automation and empower your systems to learn, adapt, and act, because your future factory isn’t just connected but agentic.

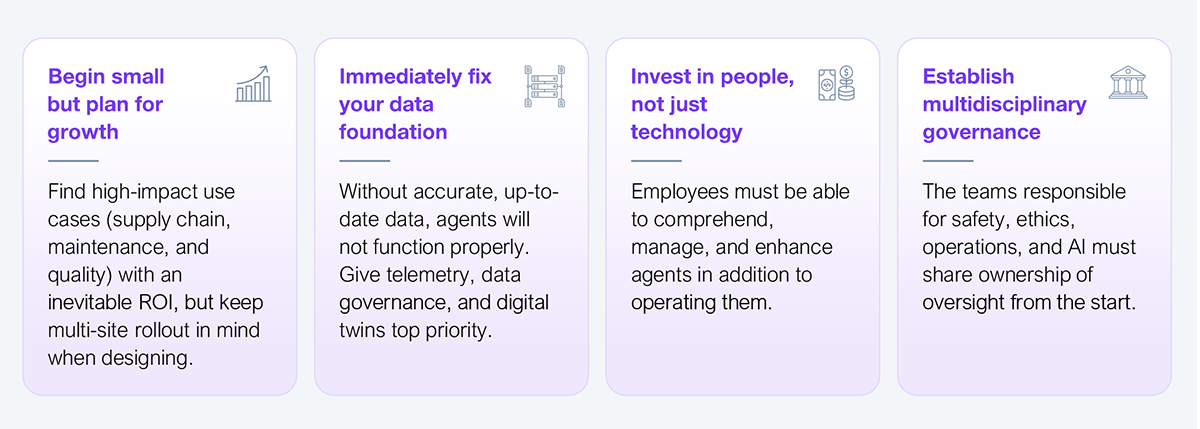

While most manufacturers rely on legacy technology for their automation needs, many are now adopting a wait-and-see approach to assess actual ROI. However, true progress demands proactive leadership when it comes to modernizing legacy systems, improving data management, and upgrading governance policies. Fostering a culture of adaptability and risk-taking can drive substantial improvements in efficiency and competitiveness. Leaders should also shift their focus from merely planning tasks to defining clear objectives, anchored on four pillars (see Exhibit 3), and move from execution to establishing effective processes. Employee training and development are also essential for enabling this shift, ensuring they are well equipped to handle advanced technologies.

Source: HFS Research, August 2025

Some manufacturers are already proving that real, measurable ROI is achievable and accelerating. For instance, Siemens’ Amberg facility, a global benchmark in smart manufacturing, has integrated autonomous agents that adjust production parameters in real time, significantly improving yield while reducing waste. Similarly, Bosch’s industry 4.0 factory in Blaichach uses self-optimizing systems driven by AI agents to detect equipment fatigue and schedule pre-emptive maintenance autonomously, cutting downtime by nearly 25%.

The key question for business executives and manufacturers is no longer about embracing agentic AI but whether they’re prepared to scale with it. The tech replaces passive monitoring with autonomous execution, solving problems before humans even notice, but such autonomy can’t thrive on fragile, outdated infrastructure. Legacy systems must evolve into intelligent ecosystems that are modular, connected, and data-fluid to support decision-making agents that scale.

Tomorrow’s leaders are already letting go of centralized control today. They’re designing for autonomy, enabling digital co-workers to drive action, and trusting agents to pursue outcomes.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started