Every supply chain failure now exposes the same flaw. In essence, enterprises still manage linear systems in a nonlinear world. Agentic AI is collapsing those silos in real time — turning decades of supply chain interoperability dreams into operational reality. CSCOs who don’t act will soon find themselves managing disruption instead of driving it.

Without shared intelligence, resilience is an illusion

As long as suppliers, distributors, and logistics partners run on fragmented data, resilience remains an illusion. Moreover, it’s almost impossible for a single stakeholder in the supply chain network to have complete visibility and make changes at runtime. A group of AI agents deployed across the supply network can bridge that gap, making the once elusive dream of interoperability finally within reach.

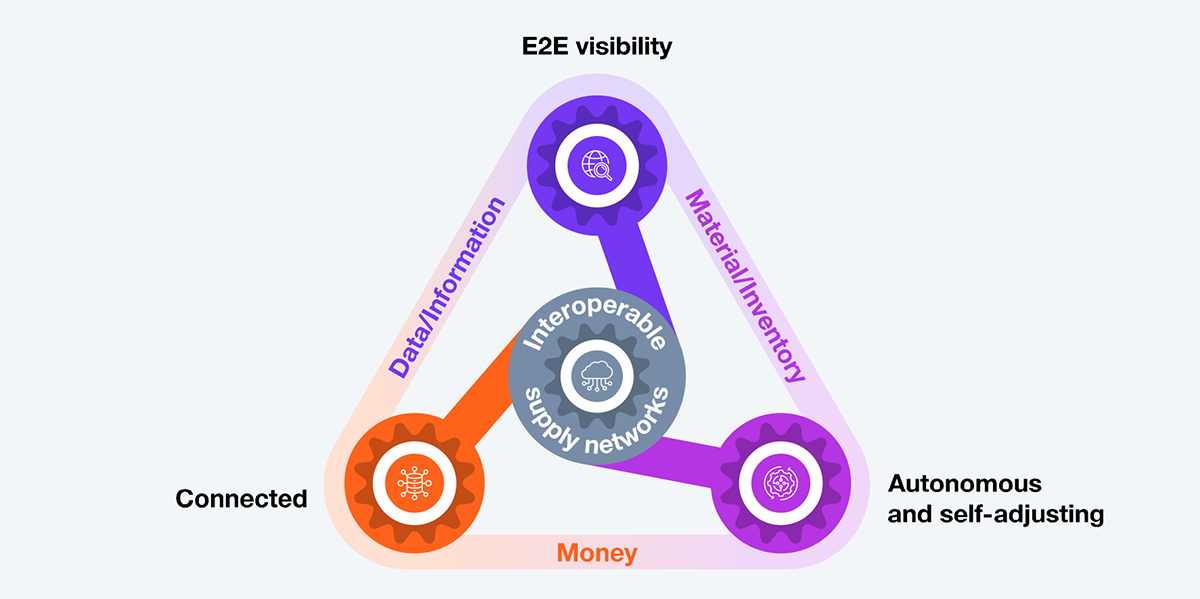

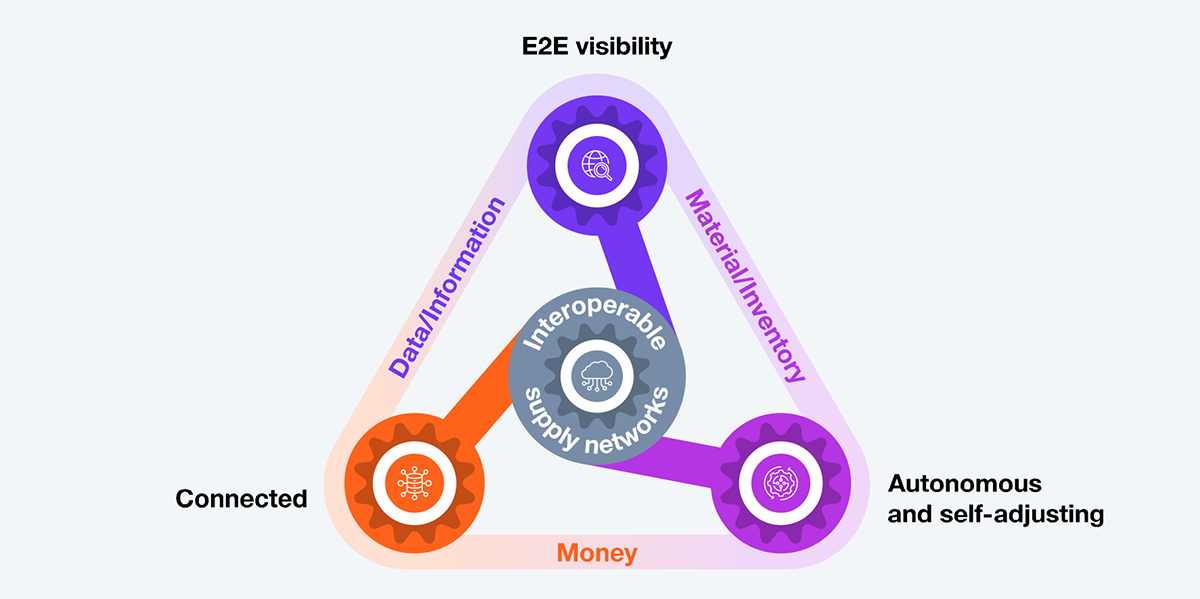

This sets the foundation for interoperability (see Exhibit 1), a shared operating state spanning money, data, and material, where a change in one node updates the rest of the supply network with minimal human choreography. There are three building blocks to this:

- End-to-end visibility to see what’s happening before it costs you. It predicts where the next failure or delay will strike. AI-driven sensing across suppliers, production, logistics, and payments gives CSCOs a real-time economic map of their operations. When you can see the flow of working capital and material at once, you can stop losses before they appear in the P&aL.

- Shared intelligence where you decide once, and act everywhere. A single, shared intelligence layer ensures that every stakeholder—from finance to fulfillment —acts on the same data, not competing versions of it. Agentic AI doesn’t just report status; it drives consensus in milliseconds. When the network agrees on one version of truth, performance optimization becomes collective accountability, not a firefight between functions.

- Autonomous and self-adjusting to orchestrate change faster than disruption. Interoperability peaks when the network self-corrects. A change in one node, such as an order, payment, or quality alert, automatically triggers synchronized actions across the ecosystem. The goal is not automation for efficiency, but autonomy for resilience where supply engines can sense, decide, and act without waiting for permission.

Exhibit 1: An interoperable supply network—a shared, live operating state across partners

Source: HFS Research, 2025

When these three capabilities align, interoperability becomes a living operating state—one where value, not visibility, defines control.

Agentic AI turns weeks of orchestration into hours of self-correction, and the economics are staggering

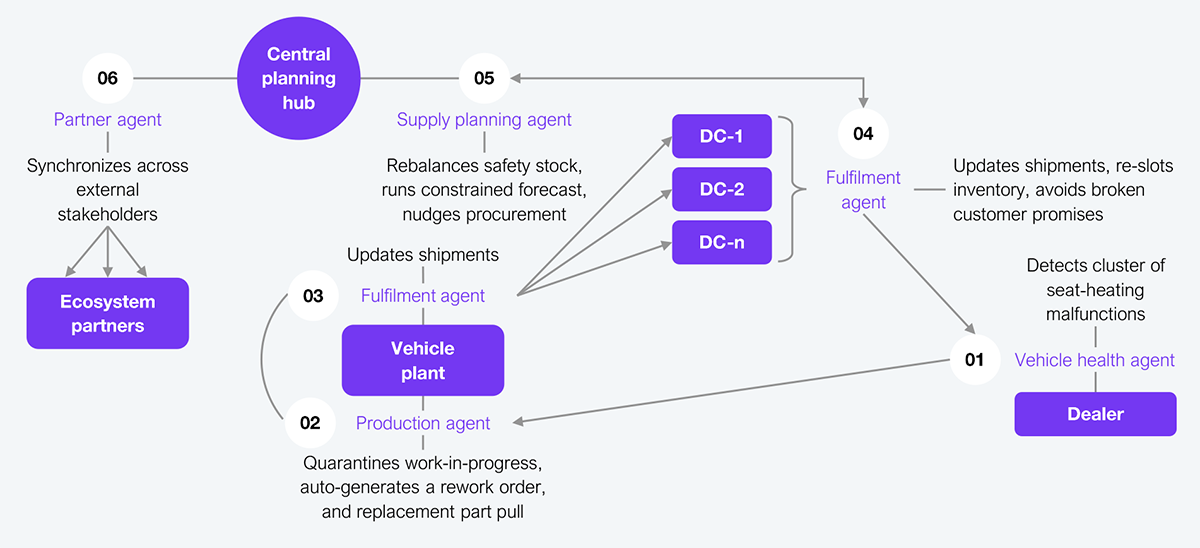

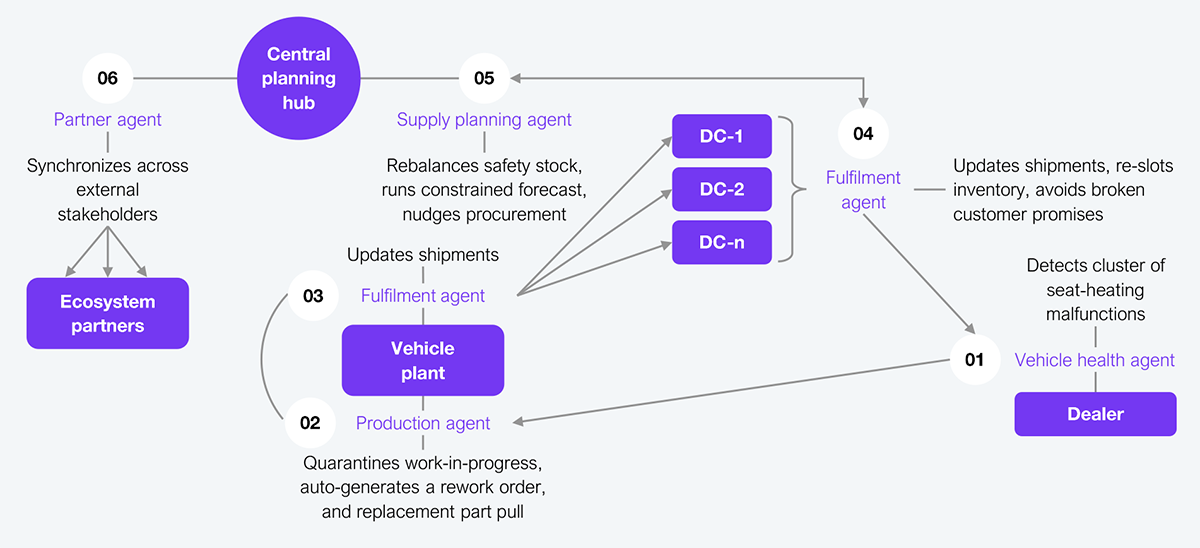

A leading German automotive manufacturer has been leveraging AI agent orchestration (see Exhibit 2) to build an interoperable supply chain. The agentic pattern shows how a three-week process now takes hours, using an approach as follows:

- A vehicle health agent detects a cluster of seat heating malfunctions and raises a quality trigger tied to the affected batch.

- A production agent at the plant acknowledges, quarantines work in process with the same batch, and auto generates a rework order and replacement part pull.

- A fulfillment agent updates shipments and notifies distribution centers to re slot inventory, avoiding customer facing promises that can’t be met.

- A supply-planning agent readjusts short term demand and safety stock, rolls the impact into a constrained forecast, and nudges procurement.

- A partner agent posts an EPCIS event set into the data space so suppliers and service centers see the same ground truth.

Exhibit 2: Agentic AI turns disruption into a self-healing advantage for manufacturers

Source: HFS Research, 2025

The result: a 90% reduction in latency, near-zero scrap, and a supply engine that thinks faster than disruption.

Nine in ten CSCOs are stuck in pilot purgatory and running blind in an automated economy

Despite billions in AI investment, 90% of CSCOs remain stuck in pilots—watching competitors convert automation into margins. Out of 460 senior supply chain leaders surveyed, less than 10% have implemented GenAI at scale across their operations, while more than 80% reassessed or delayed their GenAI program in the past 12 months. When asked why, leaders cited five major roadblocks: data readiness, skill gaps, security risks, complexity of integration, and regulatory compliance. They also flagged risk factors such as infringement of privacy laws, increased cybersecurity threats, and fear for brand reputation. This isn’t a technology failure, but a leadership paralysis. Enterprises that wait for readiness will evaporate.

In sum, while the technical scaffolding to construct truly interoperable supply chains via agentic AI is now firmly in place, what’s missing is conviction and organizational readiness.

Make these five moves to break out of pilot purgatory

HFS Research identified five decisive moves separating pilot-stage enterprises from production leaders:

- Start with collaboration and end with ecosystem control. Cross-functional collaboration must be the first design principle. But the real advantage starts when that collaboration extends beyond internal teams to suppliers, logistics partners, and customers. Shared data and aligned incentives turn coordination into real-time orchestration.

- Use cloud for speed, not scale for its own sake. Cloud is the prerequisite for deploying and scaling agentic AI. Enterprises that treat cloud as a cost-control solution end up building walls where they need runways. Cloud-first architectures collapse deployment time and amplify AI responsiveness.

- Build a complementary tech stack, not a tech zoo. HFS data shows that firms scaling GenAI pair it with adjacent technologies such as IoT, robotics, and blockchain, but with discipline. Interoperability requires integration, not accumulation. AI delivers value only when it’s embedded across the entire stack.

- Govern AI like capital, with rules, risk, and return. The biggest barrier isn’t technology but trust. Governance must move from compliance paperwork to operational discipline, incorporating risk frameworks, transparent use cases, and continuous audits. It is now the backbone of both AI credibility and enterprise trust.

- Measure outcomes that fund themselves. The CFO lens is now non-negotiable. The next phase of AI investment will die without proof of value. Replace productivity metrics with performance KPIs such as reduced inventory days, faster order cycle times, and higher capital velocity.

The bottom line: Interoperability isn’t a technology strategy. It’s a matter of survival.

CSCOs who keep running chains will keep breaking them. Those who build agentic AI–powered networks will run enterprises that can think, adapt, and win in real time.