Factories in the micro, small, and medium enterprises (MSME) segment are weighed down by decades of tech debt resulting from fragmented growth, suboptimal application development, and diverse manufacturing systems, choking their ability to modernize operations. About 70% of digital transformation budgets are allocated to sustaining such archaic systems, restricting innovations.

Advanced AI is the jackhammer that factory managers need to break through these challenges and constraints while enabling speed, accuracy, and rational execution in the overall ecosystem of manufacturers and suppliers that are highly dependent on each other.

Tech debt stops enterprises across sectors from embedding advanced AI into existing systems, limiting their ability to innovate and solve large-scale, complex problems. The root causes are mainly poor quality and bespoke code, skill shortages, and over-reliance on system integrators.

Advanced AI can tackle this through a range of capabilities: GenAI, small language models (SLMs), natural language processing (NLP), and agentic AI. GenAI can address code challenges through automation and data analysis to identify and fix inefficiencies, while unified data mapping provides a common data standard across inconsistent naming conventions. SLMs can process information across diverse systems. NLP can share information by talking in “one language” across diverse systems for seamless integration and interoperability. Lastly, agentic AI can take autonomous decisions, with humans in the loop.

Large enterprises, in particular, are using these advanced AI capabilities to reduce tech debt as part of their modernization efforts, setting a precedent for MSMEs to follow. Volkswagen, for instance, implemented its Digital Production Platform to standardize systems in its production sites worldwide, delivering medium-term savings in the double-digit million range. As this shift accelerates, MSME suppliers are likely to receive support from large enterprises in their journey toward modernization, driving mutual gains.

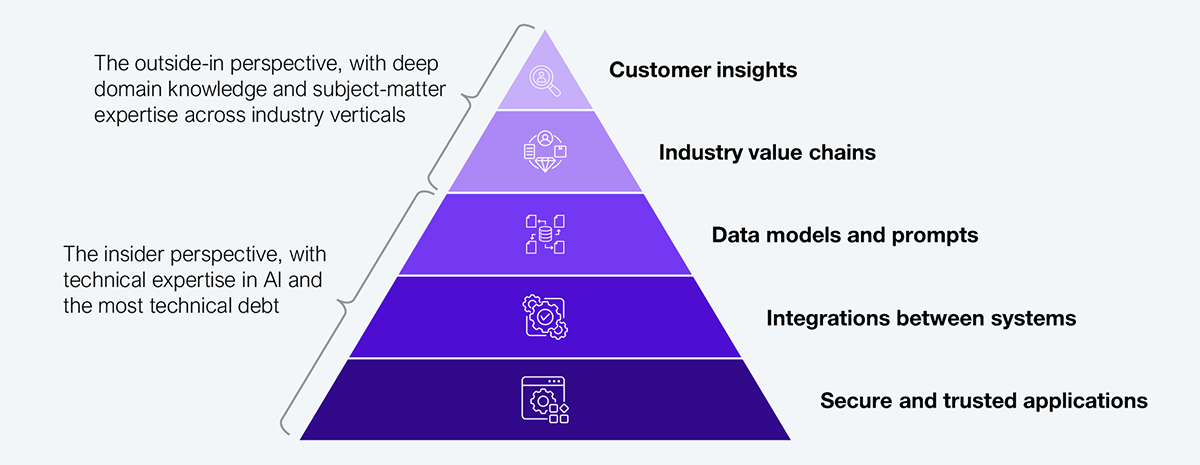

AI is a complex, multilayered technology. NVIDIA CEO Jensen Huang recently described it as a five-layer cake comprising energy, chip, infrastructure, models, and applications. Building on this, R Systems introduced a framework (see Exhibit 1) with layers to tackle tech debt. This includes: 1) applications built with security and trust; 2) integrations or connections across systems; 3) data models and prompts; 4) industry value chains for domain expertise; and 5) customer insights. Investments happen mainly in the first three layers, where most of the technical debt lies and must be addressed for quick returns.

Source: R Systems, HFS Research, 2026

R Systems also shared a cross-sector perspective, outlining three opportunities to help companies transform into autonomous enterprises through advanced AI systems. This includes: 1) embedding AI capabilities and features into existing products, platforms, and systems to create new value, 2) opening up new use cases, and 3) using AI to solve big problems. The first and third opportunities are supported by proven technologies and showed tangible results: increased IT cost savings and no more duplicate data sources, applications, and infrastructure.

Siemens’ Industrial Copilot, developed in partnership with semiconductor manufacturer Global Foundries, demonstrated these benefits by rapidly generating, optimizing, and debugging complex automation code. Another example is GE Aviation’s AI Wingmate that allows employees to leverage GenAI for various tasks, from getting instant access to information and enabling faster learning for complex problem solving to generating content such as documents.

Many sectors are limited not by a lack of AI potential, but by legacy systems that restrict visibility and slow decision-making. When AI unifies data flows, automates diagnostics, and surfaces insights in real time, the impact is immediate and tangible. Our work at R Systems focuses on modernizing these core systems so enterprises can move from isolated improvements to truly adaptive, AI-driven operations.

— Nitesh Bansal, CEO and MD, R Systems

For the manufacturing sector, specifically factories, private SLMs with interoperability are a cost-effective way to address common problems such as limited visibility over complex production processes and difficulties in performing root-cause analyses on factors affecting productivity.

Private SLMs are industry or enterprise-specific manifestations of GenAI, capable of understanding, processing, and generating content in natural languages. With their on-premises deployment option, they are particularly effective for shop floors that are not connected to the internet. When built as a wrapper around existing systems, they can power Copilot to handle queries and allow employees to use NLP for root-cause analyses and report generation.

Bosch, for instance, used NLP to convert large volumes of unstructured data into multilingual knowledge, benefiting employees in domains such as materials science. Similarly, Airbus implemented an AI assistant with a chatbot that gives employees standard operating instructions for aircraft assembly while facilitating access to technical data in natural language.

R Systems’ partnership with a leading industrial AI company enables these capabilities at scale. Its Namespace rationalizer tool maps old data naming conventions to new corporate standards for applications such as unified analytics, ultimately reducing tech debt. By applying GenAI to the traditional manual data mapping process, factories can shrink the mapping cycle time with higher levels of accuracy, turning to subject matter experts only when required. Toyota, for example, implemented a unified data layer that gives engineers single-point access to multiple systems rather than logging into each one separately, reducing the time taken for decision-making.

While GenAI creates content to manage the challenges with legacy applications, agentic AI takes decision-making and execution a step further to address tech debt by making changes to code, data sets, or their mapping across systems. Current Copilot factory implementations integrate with enterprise systems such as MES and ERP to build a data model. Futuristic implementations can make these integrations bi-directional, not just to sense what’s happening in the factory but also to take timely actions autonomously and send the necessary instructions to the right system. This is an example of IT-OT integration for seamless communication between the shop floor and the top floor or the rest of the enterprise.

With manufacturing becoming a cohesive ecosystem of factories and multi-layer suppliers with a seamless flow of goods and information, one’s tech debt can drag the efficiency of the entire interconnected ecosystem. Address this first with minimal reengineering and advanced AI capabilities, especially before making any major investments.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started