That’s the experienced view of a senior manager leading the “digital workforce” and his organization’s RPA center of excellence (CoE) at a US consumer products business.

The leader in question runs the CoE out of the organization’s IT department. He focuses on finding ways to support the human work in the business through automation. Another automation CoE looks after streamlining the business’s manufacturing processes through automation.

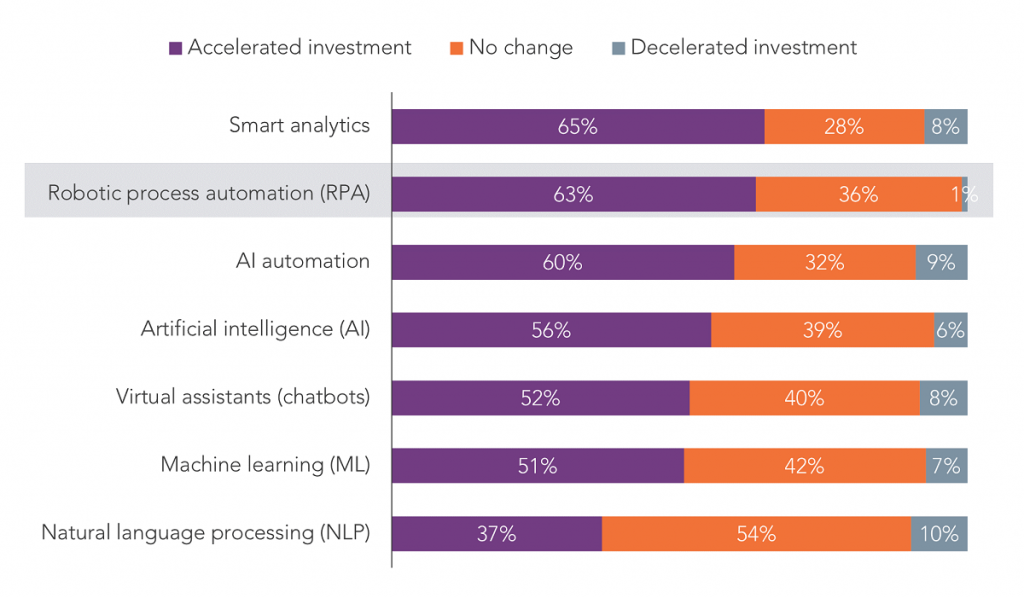

Investment in automation accelerated across almost all enterprises as a result of the COVID-19 pandemic. Businesses sought solutions that supported shifts in where people worked – and helped them tackle labor shortages. HFS data – (shown in Exhibit 1) found 99% of 400 Global 2000 enterprises surveyed had either increased or maintained their investment in RPA.

Sample: HFS survey, March 2021, 400 of the Global 2000 enterprises

Source: HFS Research, 2022

Rapid market and technology adoption over the last two years revealed a raft of new automation opportunities for this company, which prefers to remain anonymous on this occasion. The company had to carefully manage the opportunity to avoid adding fear of job loss to anxieties employees were already facing in a period of rapid change.

The company can credit employees’ warm embrace of automation to careful internal outreach. It avoided using the term “bots,” using “digital assistants” instead. Teams felt they were getting a welcome helping hand at just the time they needed it.

Starting with the low-hanging fruit, the “digital workforce” team (the humans running the introduction of the digital assistants) expanded its footprint into finance, IT, and HR. The internal outreach did its trick. Previously, members of the CoE had to go from stakeholder to stakeholder, explaining the virtues and capabilities of RPA and wider automation; now, there was a steady queue of willing managers seeking some digital assistance.

The business had been working with Automation Anywhere since 2018, beginning with relatively simple tasks. The company initially prioritized manual daily or weekly tasks. They wanted tasks that would impact the whole organization, such as customer service. Their approach was to start small but with impact, then scale.

Learning from those initial small projects proved to be their formula for success. RPA had been sold to the business as something that delivers fast results. It can deliver value if IT uses it in conjunction with the business, explained the company automation leader.

Starting small gives lean teams, like his own, the opportunity to learn the technology as they go, understanding development lifecycle requirements, going next to a proof of concept, and, as the technology proves its value, scaling out.

Scaling out often means repeating the lessons learned in automating a process that gets proven by delivering success with one of your customers (for example, in saving time managing invoices), using modular design, then repeating the process for another 10 or 20 customers. From a small initial test-and-learn trial, you are soon making big impacts, he said.

He believes that it is only once you are comfortable with the technology and your internal processes that you should attempt anything bigger and more complex. As a best practice, his team avoids activities that will take more than a couple of weeks of effort, limiting the scale of what they take on and preventing scope creep.

If you need a guide on where to target, his advice is to look at where your headcount is. Often, the more people that are engaged, the more impact RPA is likely to have.

Automation Anywhere (AAI) has been the company’s go-to technology for process automation thanks to its range of capabilities including process discovery and Intelligent Data Processing (IDP), and the fact that AAI’s cloud-native architecture aligns with the customer company’s ambitions to support its people’s ability to work from anywhere.

When a project requires data structuring, the company also applies Python. It uses Microsoft Power Automate for some simpler, lower-impact processes.

While the human work CoE team is considering process intelligence tools, it has been satisfied to date with Automation Anywhere’s Discovery Bot, which follows a process and creates the steps. The automation leader describes this as a great first pass but has found it is always wise to meet with the process owners to hone the process, identifying exceptions and error handling requirements. Automation Anywhere recently acquired FortressIQ and will be integrating its higher-level process intelligence capabilities into its suite.

Automation Anywhere deploys its intelligent document processing (IDP) product, IQBot, to digitize and support invoice processing. The automation team plans to add desktop support for employee productivity with the platform’s AARI interface.

Projects are delivering between 2:1 and 5:1 ROI. The consumer goods company measures ROI by benchmarking any automation proposal versus the headcount, time taken, and other resources required to deliver, as is. They establish KPIs to compare what the bots deliver to what the humans can do and how many hours the project can return to the business for value-add activities.

Now the business is running more than 50 bots and saving approximately 2,000 hours of human work each month.

In some cases, automation has made it possible to deliver value that would not have been possible without it. For example, when buying the resin it uses in many products, the consumer goods company faces a settlement window and a discount window. Optimizing the discount available requires processing hundreds of invoices in a period in which the available human resources could not hope to deliver. Automating the process delivers discounts worth hundreds of thousands of dollars with one vendor alone. Scale that to all vendors, and the benefits are obvious.

Among the biggest benefits the automation leader identifies is the opportunity to review and improve processes. The ambition is to go beyond task-based automation and to deliver end-to-end outputs. They started with tasks, and as they met each stakeholder, they found where their task ends, the handoffs, the gaps, and where alerts and triggers can be applied to handoff from one bot to another, with some human validation. With appropriate scheduling, bots talking to bots to execute full solutions is rapidly becoming a realizable ambition.

The automation leader we interviewed says his automation journey has taught him three lessons automation program leaders would be wise to apply:

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started