The chemical industry is yet to move past AI hackathons and pilots to achieve large-scale implementations, delaying AI-related gains in margins, compliance, and efficiency. Unlike other sectors, chemical manufacturers are hamstrung by legacy enterprise resource planning (ERP) and applications, fragmented data, high costs, and regulatory pressures due to their asset-heavy, capital-intensive, and safety-first nature of the business.

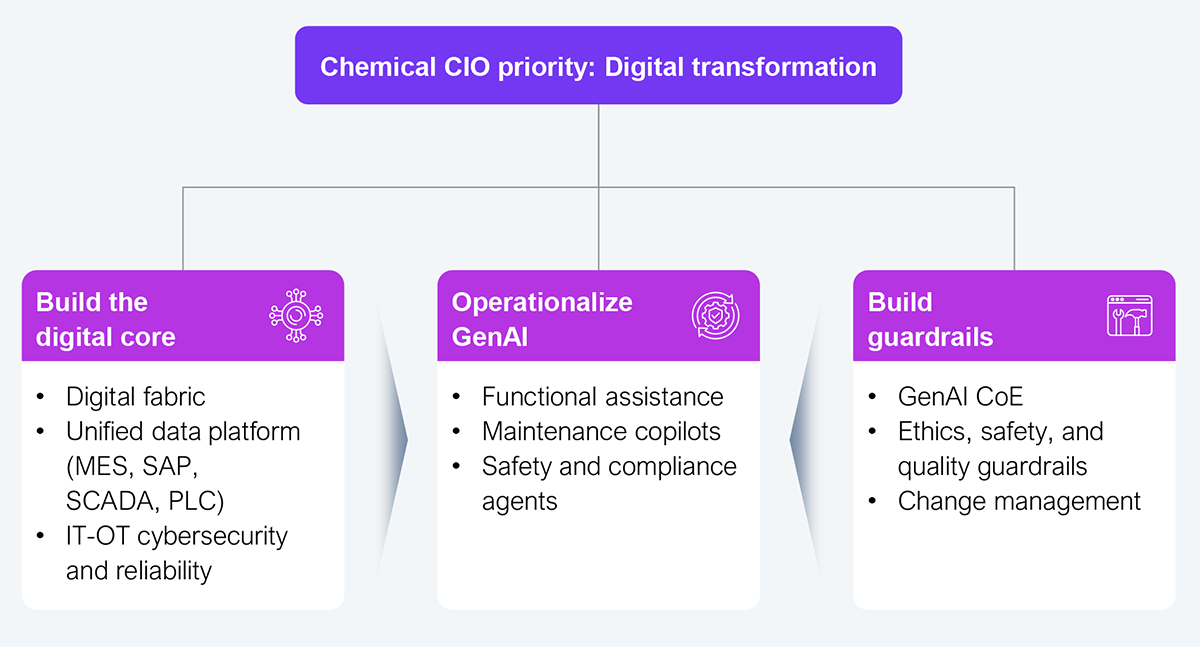

Operationalizing AI can address these issues while delivering both short and long-term gains. This includes shifting the focus to execution while aligning to three business priorities: establishing a robust data core, building AI guardrails, and operationalizing GenAI for industrial use cases (see Exhibit 1).

Source: HFS Research, 2025

The chemical industry is one of the oldest, holding large volumes of data in legacy systems. AI can unlock valuable insights, inferences, and innovation for new products, but realizing this requires unifying the digital infrastructure. This involves bringing together decades-old operational technology (OT), information technology (IT), ERP, supply chain, and emissions data with a cybersecurity layer in the business-led AI architecture. Without trusted and structured data, operational alignment, and board-level oversight, even the most ambitious AI roadmap will collapse under its own complexity.

Digital pilots and functional agents have evolved into essential components for the chemical industry. Large companies are already building the digital core by leveraging cloud and fabric technologies to operationalize copilots for multiple functions. Data fabric or fabric technologies pull data from legacy and new systems, clean it, and make it available for copilots and apps in a consistent manner. For example, Eastman Chemicals migrated its data to Microsoft Azure and Fabric by leveraging built-in analytics and warehousing and analytical capabilities to integrate a sales copilot directly into its customer relationship management (CRM) system. This shift to a distributed and domain-oriented architecture gives their sales team immediate access to customer and product data, enabling them to prioritize conversations over data point collection.

Long-term strategies such as BASF’s transition to an SAP S/4HANA Cloud core can streamline processes and provide real-time master data for sourcing decisions, laying the groundwork for AI and sustainability initiatives. The company has already launched SAP Joule Copilot, which provides contextual insights and helps users navigate SAP applications more efficiently by allowing them to ask questions in natural language. Without a clean, cloud-ready core in procurement and supply chain, AI projects will struggle to deliver results.

To facilitate this migration, CIOs must establish ownership of master data, including materials, products, and suppliers. They must ensure that the core data is accessible through APIs to support analytics, AI-driven downstream platforms, and functional applications to increase productivity in the long run.

Every AI deployment has a checklist to eliminate red flags and risk factors related to cybersecurity, ethical AI, compliance, auditability, explainability, and accountability. Aligning platforms, partners, and personnel with corporate goals can maintain cost control, compliance, collaboration, and change management. Also, establishing an AI governance council that includes board members and executive leaders will ensure higher outcomes, better value, and secure API contracts with defined service-level agreements (SLAs).

For CIOs, the goal is to recognize that AI deployments are accelerators and efficiency enhancers, not intended to replace humans in the enterprise. Some companies are already taking the lead: chemical manufacturer Evonik Oxeno upgraded its OMP Unison Planning platform to enable daily simulations and real-time scenario adjustments, allowing planners to prioritize strategic decision-making and helping employees make effective procurement decisions. Once the data core and governance are in place, CIOs can focus on operationalizing and leveraging multi-scale and multi-functional agents to realize new sources of value.

To maximize outcomes from historical data, AI agents must be deployed alongside human expertise. Once the foundational IT-OT and data core is fixed, the focus should shift to “high-leverage GenAI assistants,” industrial agents that embed intelligence into daily workflow. These agents would be part of the operations, R&D, supply chain, maintenance, safety, engineering, and corporate functions to drive real outcomes.

For example, Clariant, a Swiss specialty chemical company, is seeing significant results with its data management and governance. In mid-2025, it launched its own GenAI tool called Clarita, which runs on its own IT systems to protect its intellectual property. Clarita connects R&D staff with scientists and decades of chemical literature. It also provides insights to sales teams before client meetings, tracks energy consumption at the plant, and recommends process optimization, leading to cost savings and sustainability benefits.

Similarly, Dow has introduced freight agents across logistics and shipping to review freight rates, accrued costs, and invoice rates, ensuring they’re aligned with negotiated terms in both domestic and international supply chains. The agents used color-coded indicators to flag discrepancies, noncompliant invoices, and billing inaccuracies and surfaces the data in a dashboard for employees, all made possible while creating the Integrated Data Hub using Copilot Studio.

CIOs must shift their IT and OT systems to a cloud core, such as S/4HANA or Microsoft Fabric. This involves fixing any inconsistencies, standardizing data flow, and creating structured and reliable master data using APIs. Additionally, they should implement AI in key areas that support both short-term and long-term goals.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started